Industrial air coolers are essential tools in managing workplace environments, particularly in regions where temperatures can hinder productivity and safety. This article explores how these industrial air cooling systems not only maintain a cool atmosphere but also significantly improve the safety and comfort of workers.

Importance of Workplace Safety and Comfort

Maintaining a comfortable temperature in the workplace is crucial not only for comfort but also for safety, especially in industrial settings where the consequences of overheated environments can be severe. High temperatures can lead to heat stress, a condition characterized by symptoms like dizziness, dehydration, and fatigue, which can significantly impair a worker’s ability to perform tasks safely and efficiently. Moreover, prolonged exposure to excessive heat can result in more serious heat-related illnesses such as heat exhaustion or heat stroke, both of which could be life-threatening if not promptly addressed. Therefore, implementing effective temperature control measures is essential. These measures not only prevent potential health issues but also enhance overall workplace morale and productivity. When workers are comfortable, they are less likely to be distracted by extreme temperatures, allowing for better focus and efficiency in their tasks. Additionally, a well-regulated temperature is a key factor in preserving the integrity of equipment and materials, which may be sensitive to heat and humidity levels. Overall, prioritizing safety and comfort through adequate temperature control is not just a health and safety measure but also a strategic business decision that can influence long-term success.

Understanding How Industrial Air Coolers Work?

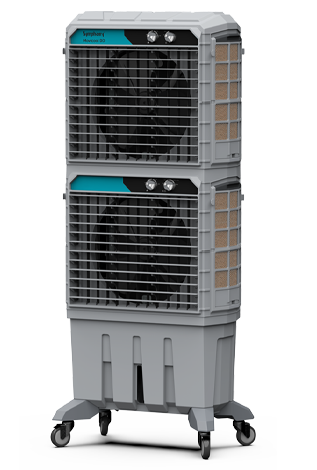

Industrial air coolers are engineered to provide effective cooling in various industries. The core components of these systems typically include a fan, cooling pads, a water reservoir, and occasionally an ice compartment to further enhance the cooling effect. The fundamental principle behind the operation of these coolers is evaporative cooling. This process involves the fan drawing warm air from the environment and passing it over the water-soaked cooling pads. As the warm air crosses these pads, water from the pads evaporates, which requires heat energy from the air. This heat exchange naturally lowers the air’s temperature. The cooled air is then circulated back into the environment, reducing the overall temperature. This method of cooling is particularly effective in dry climates where the evaporation can occur more readily, thus providing significant cooling to the surroundings.

Implementation Strategies

Implementing an industrial air cooler system effectively requires a strategic approach that starts with a thorough assessment of the workplace’s specific needs. This initial step involves evaluating factors such as the size of the space, the average temperatures, humidity levels, and the nature of work performed. Understanding these elements helps in selecting the right type and size of air cooler to meet the environmental demands efficiently.

Once the appropriate system is selected, the next crucial step is its installation. Effective installation is a key to maximizing the benefits of air coolers. It is important to ensure that the air cooler is strategically placed to optimize air flow and cooling coverage throughout the workspace. Professional installation is advisable to avoid common pitfalls such as obstructing airflow or inadequate water connections, which can significantly diminish the system’s effectiveness.

Lastly, regular maintenance and care are essential to sustain the longevity and efficiency of the cooling system. This includes routine checks and cleaning of filters, cooling pads, and water reservoirs, as well as ensuring that all mechanical components are functioning properly. Regular maintenance not only prevents unexpected breakdowns but also ensures that the cooler operates at optimal efficiency, providing consistent comfort and safety in the workplace. These implementation strategies, when executed correctly, can significantly enhance the functionality and benefits of industrial air coolers.

Conclusion

Industrial air coolers play a pivotal role in enhancing workplace safety and comfort. As critical components in maintaining optimal working conditions, these systems help mitigate the risks associated with high temperatures, including heat-related illnesses that can severely impact worker health and productivity. The importance of such cooling solutions becomes increasingly evident in industries where the environment can reach extreme temperatures.

Looking forward, as technology continues to advance; we can anticipate significant improvements in the efficiency and effectiveness of industrial air coolers. Innovations may include more energy-efficient models, greater environmental sustainability, and systems that can adapt more dynamically to varying climatic conditions. These advancements are expected to further enhance the appeal of air coolers across various industries globally, making them even more integral to creating safer and more comfortable work environments. This evolution in cooling technology promises to bring better health outcomes for employees and also broader operational benefits for businesses, emphasizing the continuing importance of investment in such essential infrastructure.