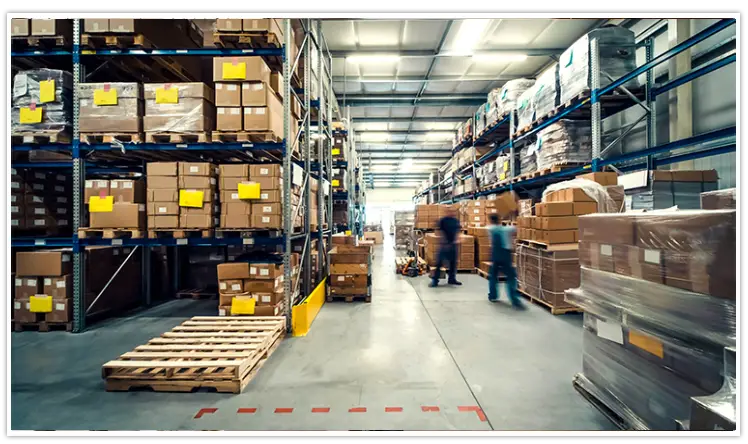

Warehouses are large spaces with high ceilings, usually based on the outskirts of a city. They are used for storage of goods of all kinds, from light-weight cartons to heavy-load goods. They play a vital role in logistics, wherein goods are stored and moved from one place to another.

Warehouses are managed by on-ground staff, who use manual means as well as heavy-weight machinery to move the goods around. Due to these factors, tremendous heat is generated in the interior of a warehouse, leading to high temperatures that are unsuitable for working.

Taking into account the current pandemic situation and the pre-existing conditions, industrial air cooling is the optimum solution for better ventilation in warehouses. Industrial air cooling works on the simple principle of evaporative air technique. It is imperative that labour-intensive and machinery-filled warehouses install industrial air cooling for the following reasons:

1. Minimised Costs, Minimum Spends

For cooling a large space like a warehouse, it is essential to note that the capital costs involved in the installation of industrial air cooling is minimal compared to other central air conditioning options. According to costing assessments, the average cost of setting up an air cooling system is one-fourth of the other alternatives. Additionally, energy consumption in running industrial air coolers is 90% less than other alternatives, resulting in minimised electricity spends.

2. Increased employee productivity

There is a specific range of temperature and humidity that humans find comfortable working under. High temperatures can lead to increased stress, which results in loss of productivity. Maintaining a cool temperature leads to an increase in worker morale, lower stress-induced errors, and ensures a harmonious relationship between the workforce and warehouse management.

3. Smooth functioning machinery

Warehouses are packed with heavy-load goods and machinery which generate massive amounts of heat. A cooling solution is vital so that the machinery continues to function smoothly and without any damage to their parts. Industrial air coolers are the only workable solution to cool a vast area and keep the goods in proper condition.

4. Reduced carbon footprint

Industrial air coolers are eco-friendly as they do not emit any CFCs or harmful gases. Fresh, filtered and cool air is circulated continuously throughout the warehouse replacing the stale air.

These facts are tested and proven. Companies including Nestle, Patanjali and Flipkart have adopted Symphony Industrial air cooling solutions for their warehouses successfully. Symphony has completed over one million installations of Industrial air cooling around the world so far.