Industrial and commercial establishments often operate in challenging environmental conditions from soaring indoor temperatures to limited air circulation in large or semi-open areas. These conditions negatively impact both human productivity and machinery efficiency. That’s why Symphony’s industrial air coolers, especially the Large Space Venti-Cooling range, are engineered to deliver powerful, eco-friendly, and cost-effective air cooling and ventilation.

This article explores how Symphony’s Venti-Cool series and industrial air coolers support productivity in harsh environments through superior design, durability, and versatile applications.

The Need for Cooling in Industrial and Commercial Spaces

Large industrial units, warehouses, showrooms, religious halls, and workshops often suffer from:

- High ambient temperatures due to machine operations and lack of ventilation

- Heat stress among workers, leading to low output

- Dust, smoke, and air stagnation

- High operational costs from HVAC systems that consume excessive energy

Symphony addresses these challenges with a unique concept of air cooling + ventilation, combining the benefits of evaporative cooling with fresh air supply. Unlike standard fans that circulate hot air or costly centralized HVACs, Symphony industrial air coolers provide localized, effective, and economical cooling that supports both human comfort and equipment longevity.

What is Large Space Venti-Cooling?

Symphony’s Large Space Venti-Cooling solutions are designed to deliver ambient cooling in open and semi-open spaces. They work on the principle of evaporative air cooling—cooling hot air through water evaporation—while ensuring continuous fresh air supply through air ducts.

These systems are ideal for locations where heat accumulation can lead to poor working conditions and decreased performance. By introducing fresh air from outside, they help replace warm, stagnant indoor air with cool and oxygen-rich airflow.

Unlike traditional systems, Symphony’s solutions:

- Are cost-effective

- Require low maintenance

- Consume significantly less power

- Provide natural, breathable air

- Can operate even during partial power supply through inverters

Key Advantages of Symphony Industrial Coolers

Dual Function: Cooling + Ventilation

Models such as the Venti-Cool 22S and Venti-Cool 25U Industrial Air Cooler provide both cooling and air movement across large areas. This keeps indoor air fresh and removes heat, smoke, and pollutants.

Powerful Coverage for Large Areas

Coolers like the Movicool XXL and Venti-Cool 40 deliver high airflow, ensuring uniform cooling in large-scale environments like:

- Manufacturing units

- Packaging plants

- Large religious gathering halls

- Shopping showrooms

Some coolers can cool areas up to 2500 sq. ft., significantly reducing the need for multiple systems.

Energy Efficiency and Cost Savings

Symphony’s Venti-Cool series provides cooling at a fraction of the electricity cost of centralized air conditioning systems. Their use of evaporative cooling makes them the ideal solution for energy-conscious industrial operators.

Compared to HVACs that consume 1.5 to 3 units of power per hour, Symphony industrial coolers consume as low as 0.2–0.5 units per hour, translating to savings of thousands per month.

Ideal for Open and Semi-Open Structures

Factories with shutters, warehouses with open loading bays, and commercial sheds benefit the most from Symphony’s semi-outdoor air cooling capabilities.

High Durability and Weather Resistance

Models such as the Venti-Cool 11U and Movicool XXL are built to last, with:

- Corrosion-resistant exteriors

- UV-stabilized plastic bodies

- Heavy-duty cooling pads

- Motor overload protection

They withstand demanding use over long operational shifts without deteriorating.

Easy Maintenance

Wide openings, detachable components, and accessible ducts allow quick cleaning and upkeep. These coolers are designed for fast servicing with minimal disruption to operations.

A trained operator can conduct routine maintenance without requiring third-party service calls, keeping uptime high.

Customizable Ducting Solutions

Symphony offers custom ducted installations for industrial and commercial clients, helping distribute air efficiently to targeted zones based on layout. With the right duct design, airflow can reach specific machines, packing zones, or employee workstations directly.

Product Showcase: Symphony Industrial Coolers

Venti-Cool 22S – Industrial Ducting Cooler

- Built for duct-based ventilation and cooling

- Ideal for medium-sized factory zones

Venti-Cool 40 – Industrial Ducting Cooler

- High capacity for expansive halls and industrial bays

Venti-Cool 11U Industrial Air Cooler

- Durable, compact solution for spot cooling in heavy-duty environments

Venti-Cool 25U – Commercial Air Cooler

- Ideal for showrooms, warehouses, and mid-sized assembly floors

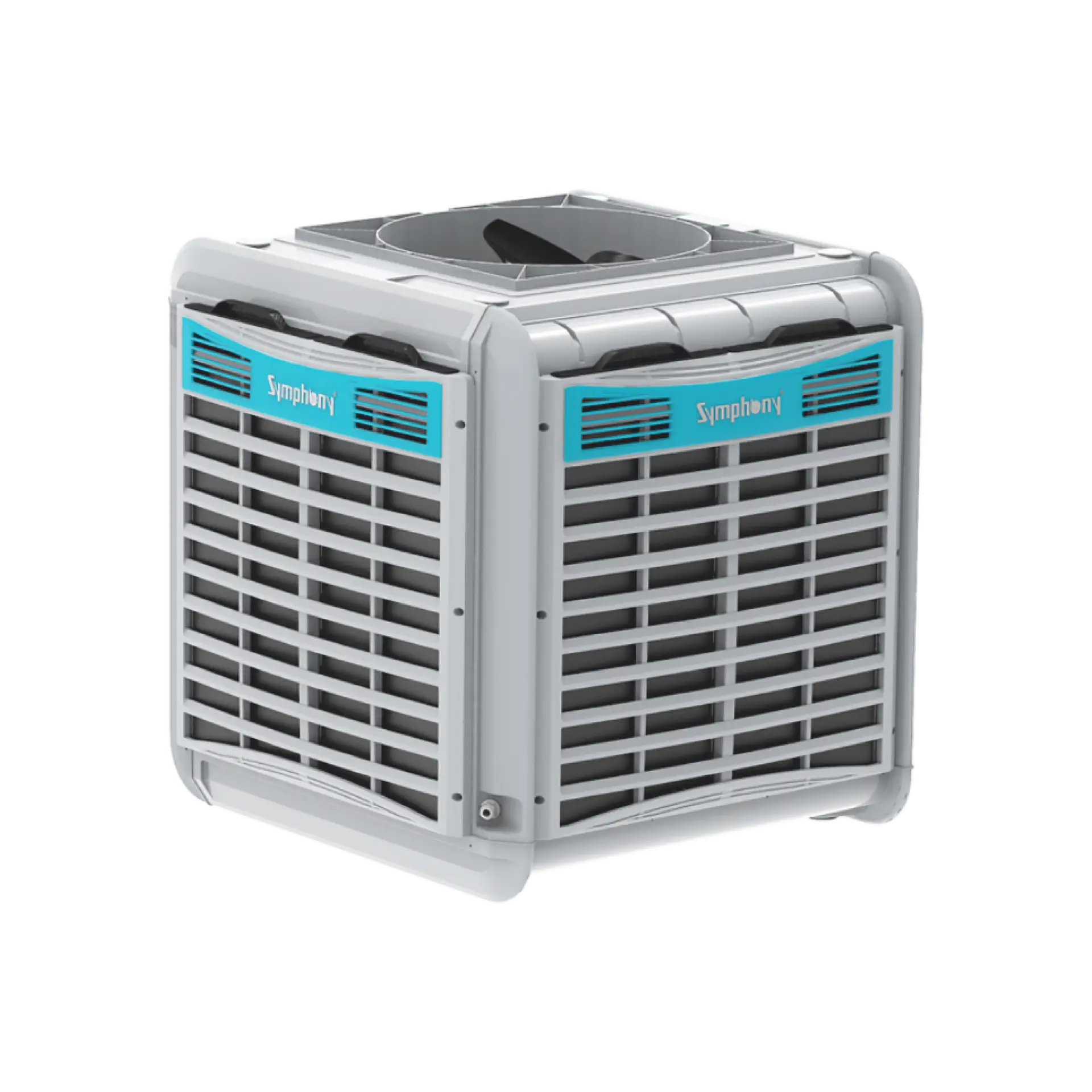

Movicool XXL – Industrial Air Cooler System

- Designed for large-scale cooling in factories, warehouses, and logistics hubs

- Covers large spaces with powerful airflow

Key Industry Applications

Symphony industrial coolers and venti-cooling systems are ideal for:

- Automotive and heavy machinery units

- Textile and garment factories

- Food processing plants

- Warehouses and distribution centers

- Packaging and printing facilities

- Retail showrooms and hypermarkets

- Religious halls, auditoriums, and community centers

They also support usage in agro-processing, ceramics, welding workshops, and metal fabrication plants where high-temperature zones are constant.

How They Enhance Productivity

Comfortable Working Conditions

By maintaining ambient temperatures and fresh air, Symphony coolers help reduce fatigue, heat-related illness, and absenteeism among workers.

Equipment Protection

Dust, overheating, and humidity are common threats to sensitive equipment. Symphony’s coolers help regulate these elements, indirectly prolonging machinery lifespan.

Reduced Downtime

Stable cooling contributes to consistent production output, fewer maintenance stops, and better product quality.

Higher ROI

With lower energy consumption and minimal setup, Symphony coolers deliver long-term savings and rapid return on investment for industrial clients.

The initial cost of implementation is quickly offset by reduced cooling expenses and improved work efficiency.

Best Practices for Use

- Position units strategically near heat-prone zones

- Enable cross ventilation with open doors or vents

- Regularly clean filters and water tanks

- Use in combination with ducting for wider air distribution

- Schedule annual servicing for optimal performance

Conclusion

Symphony’s range of industrial and large space venti-cooling air coolers offers more than just relief from heat—they provide a strategic solution to improve worker productivity, equipment longevity, and overall operational efficiency in demanding environments.

From the Venti-Cool 22S Industrial Cooler to the Movicool XXL System, these coolers are trusted across industries for their performance, reliability, and cost-effectiveness.

For factories, warehouses, showrooms, and semi-open spaces, Symphony’s smart venti-cooling systems ensure cooler, safer, and more productive workplaces.

FAQs: Symphony Industrial & Venti-Cool Air Coolers

FAQs: Symphony Industrial & Venti-Cool Air Coolers

Are Venti-Cool models suitable for outdoor use?

Yes. These are designed for open and semi-open environments like sheds and large halls.

What is the difference between Movicool and Venti-Cool models?

Movicool models are portable with very high cooling capacity, while Venti-Cool models are optimized for ducted cooling systems.

Do these models support ducting?

Yes. All Venti-Cool series are designed for efficient ducting-based airflow distribution.

What is the maintenance frequency?

Weekly tank cleaning and pad rinsing are recommended. Yearly servicing ensures maximum performance.

Can Symphony industrial coolers reduce electricity costs?

Absolutely. They consume significantly less energy than conventional HVAC systems.

What sectors benefit most from these coolers?

Manufacturing, logistics, religious centers, large retail spaces, and more.